6 common Toro PTO Clutch Problems [with Troubleshooting]

You love your garden and also love to keep it well-organized and trimmed. The Toro lawn mower has been serving this duty since its introduction. However, everything you get from your lawn mower, the PTO clutch, which is in the core.

But what if you notice your lawn mower isn’t working as usual because of Toro PTO clutch problems? There are several things that can cause such issues, including:

- Damaged or Worn parts

- Lack of lubrication

- Faulty solenoid

- Malfunctioning charging system

- Broken crankshaft

- Worn or damaged clutch bearings.

Well, as you know, every problem has a solution, but you just need to find the right solution. In the case of a Toro PTO clutch, this guide will take you to the end of such issues.

What Is A PTO Clutch On A Riding Mower?

Before getting down to the core of our discussion, let’s first become acquainted with the PTO clutch basics. So, what is a PTO clutch on riding mowers?

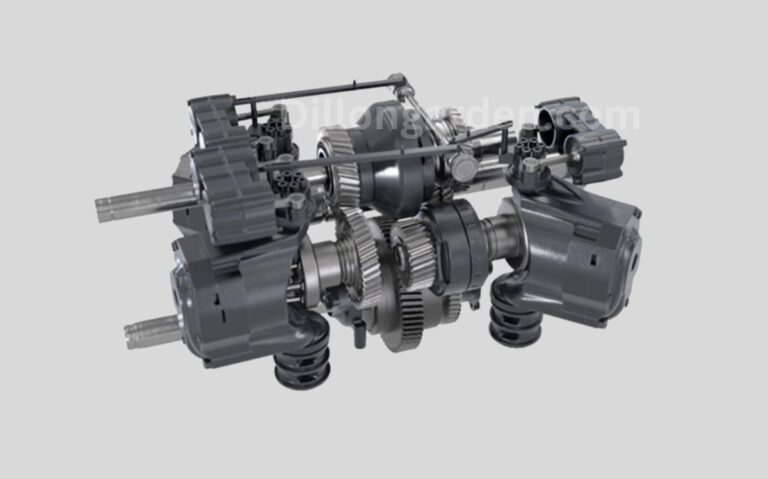

Well, the PTO clutch, also known as the Power Take-off clutch, is a crucial part of agricultural or farming equipment such as riding mowers that helps in engaging and disengaging the blade.

The key components of the clutch are the output pulley, armature, rotor, brake plates, and field assembly.

Electromagnetic PTO Clutch Breaks operate via electric actuation but transmit torque mechanically.

Generally, the riding mower has a toggle switch that controls the connection between two drive shafts facilitated by the PTO clutch.

In short, the PTO clutch is an electrical component that controls the engagement of the blade used in riding mowers. Without this, the blade would run all the time.

What does a Toro PTO clutch do?

The design, construction, and working mechanism of the PTO clutch are related to its most commonly occurring issues.

We have already described what the PTO clutch is on your Toro land mower. Now let’s shed some light on what a PTO clutch does on your Toro lawn mower.

Creating Magnetic Field

First, when you provide voltage or current to the clutch by turning the switch on, the coil becomes an electromagnet and produces magnetic flux lines.

This flux is then transmitted through the small air gap between the field and the rotor. The rotor then becomes magnetized and creates a magnetic attraction loop between the rotor and the armature.

Amplifying the Torque

As the flux travels from the rotor to the armature, it makes multiple points of contact, amplifying the torque being transferred, helping to maximize torque and reduce weight and size.

Engagement and Disengagement of the Blade

When the clutch is engaged, an air gap exists between the top of the armature and the clutch plates. Conversely, as you disengage the PTO Clutch, an air gap is created between the armature and the rotor. So there is no contact.

However, when the magnetized rotor and armature attract each other, the clutch slips for a short initial engagement period.

As the current or voltage is removed from the clutch, the magnetic field degrades quickly, and springs pull the armature away from the rotor and against the brake plate.

It causes a mechanical drag on the armature and pulley, which ultimately slows down the cutting blade.

common lawn mower clutch problems

A bad or failing PTO clutch in your Toro lawn mower means you don’t get the same output from this component.

Consequently, several symptoms will be visible, depending on the severity of the condition. So, keep your eyes and ears open, whether you notice the following signs:

- Unusual Noise

- Unexpected Power Loss

- Slow Engagement

- Fluid Leaks

- Difficult PTO Disengagement

- Extremely Hot PTO

4 most common Causes of Toro PTO Clutch Problems – will a bad pto clutch cause power loss?

The PTO clutch on your Toro lawn mower can malfunction either due to physical damage to the clutch or an electronic issue.

No matter what the situation is in terms of your lawn mower, we’re going to describe each and every possible cause and their potential fixes.

Cause-1: Physical damage issue

When you’re having something wrong with your blades engaging, the first suspect should be a physical damage issue.

This can be a misaligned clutch belt or a broken crankshaft bolt that holds the clutch in place.

Technically, when you engage the PTO clutch, there’s a bracket or a bolt that stops the clutch from just spinning around on the crankshaft.

Once that fails, it normally damages not only the clutch but also the wiring harness. Besides, the other common issue is the bearings of the clutch.

When the bearings go bad in the clutch, it creates some heat. You’re also going to hear a noise with that clutch stop bracket broken.

So, when you start up the motor, you may hear a grounding, squealing, or any of the above-mentioned issues going on.

Potential Fix:

In the case of a physical damage issue with your PTO clutch, try to follow the steps mentioned below to fix it:

- Step-1: Preliminary Inspection

Start with a visual inspection. Here, you have to first make sure the belt is in its place correctly.

- Step-2: Check the Crankshaft

Now go underneath and check whether the crankshaft bolt is broken. If it’s broken, you may not have to buy a new clutch.

However, you have to pay for it, do it yourself, or extract a broken bolt from the crankshaft, which can be very time-consuming and painstaking work.

- Step-3: Inspect the Clutch Bearing

If the belt alignment and crankshaft bolt are okay, it’s time to focus on the clutch bearing.

To determine if the bearing is broken, listen carefully to whether the clutch creates an unusual noise during the engagement. If yes, you have to replace the clutch.

Cause-2: Lack of Voltage or Faulty Charging System

Sometimes you may experience PTO clutch issues just because the charging system is not working on your motor or is lacking voltage.

For example, you’re cutting just fine, but suddenly your blades stop cutting at the end of the day, halfway through the day, or whatever.

In that situation, you should check the battery and the charging system. Because if the charging system is not working properly, the clutch is going to be the first thing to quit working.

A PTO clutch draws a significant amount of amps and volts from the battery, and once it gets weak, it’s going to just shut that off. In short, it doesn’t have enough power to power that clutch anymore.

Even though there might be enough power to keep running the mower through the coils and all that, it’s not going to have enough juice to keep that PTO clutch engaged as the battery is not being recharged.

Potential Fix:

When your PTO clutch isn’t functioning properly because of a faulty charging system, the following steps can be your savior:

- Step-1: Pick A Voltmeter

When your PTO clutch is affected by a faulty charging system, your first step should be checking the voltage. Here, you can use a voltmeter to ensure its continuity.

- Step-2: Locate the Battery

Lift the rear shield on your mower and take off the grass bag and frame. Now, make sure you’re holding onto that shield as you unscrew the mount that’s keeping the battery and fuse housing in place.

If there’s any tape sealing it up, just peel it off like a boss. Once you’ve done all that, just slide out the housing so you can get at that battery.

- Step-3: Attach the Voltmeter

Here you have to connect the positive lead of a voltmeter to the red, positive post on the battery. And then, attaching the negative voltmeter to a reliable engine source.

Take note of the voltage reading. If the battery output indicates 12.5 volts or lower, proceed to charge the battery.

- Step-4: Inspect Surrounding Components

Inspect the electrical wiring harness from the lever switch to the PTO clutch assembly under the deck for an in-line fuse. Remove and examine the cap wires connected to the fuse filament.

If you observe a black appearance or a blown filament, replace it with a fuse that has the same ampere rating as the original one.

Cause-3: Faulty Clutch Solenoid

The clutch solenoid in your Toro lawn mower acts as a bridge or switch that activates when you engage the clutch with the engine.

This solenoid automatically deactivated when the external shaft is connected. Therefore, a faulty or bad solenoid will cease the functionality of the clutch completely.

In some cases, a wrongly calibrated solenoid affects the performance of the clutch, which may not be severe.

However, no matter what the scenario, a malfunctioning solenoid should be repaired or replaced.

Potential Fix:

Here is how to fix a bad PTO clutch solenoid:

- Step-1: locate the Clutch Assembly

In order to resolve a malfunctioning PTO clutch solenoid, you have to locate the clutch assembly first. This is usually placed beneath the mower.

Before this, you have to ensure the mower is switched off and all the wires connecting the PTO clutch are disconnected.

- Step-2: Activate the Battery

Insert the key into the mower and turn it to its initial position, without initiating the mower’s operation; this will activate the battery.

- Step-3: Attach A Multimeter

Adjust your multimeter to Amperage and connect the black probe to a grounded metal component.

Subsequently, insert the red probe into the wiring harness connected to the switch. Activate the PTO switch, which should yield a reading of approximately 4 amps.

If no reading is obtained, it is probable that there is an issue with the switch. It may be necessary to contact the manufacturer for obtaining information regarding the part number for the replacement of said PTO switch.

Cause-4: Lack of Lubrication

Lack of lubrication in your PTO clutch assembly is one of many potential issues.

Due to insufficient lubrication, the machine may exhibit symptoms such as a squeaking noise or difficulty performing tasks.

This can be attributed to friction in the clutch parts, leading to sticking or improper turning.

Even with the engine at full throttle and the clutch fully engaged, you will experience resistance in mower movement, indicating a clear and relevant problem.

Insufficient lubrication of a PTO clutch not only results in power loss but also accelerates the wear and tear of clutch components, potentially causing permanent damage to the machine’s mechanism.

Potential Fix:

If you want your PTO to last for years without any issues, make sure you lube up that clutch assembly.

Applying just the right amount of grease or oil at the recommended intervals will save you from unnecessary heat and grinding that could mess up your components.

Don’t go overboard with the grease since applying too much can cause those main bearings to overheat and fail. So remember, follow the proper greasing guidelines, and you’ll be good to go!

Read also: Electric PTO Clutch Troubleshooting Guide (3 Problems Solved!)

Expert tips for maintaining Toro PTO Clutch To Avoid Problems

- Keep blades sharp

Dull blades increase resistance, forcing the PTO clutch to work harder and generate excess heat. - Maintain proper belt tension

Loose or dragging belts cause clutch slippage and accelerate friction surface wear. - Ensure a strong battery and charging system

Low voltage prevents the PTO clutch from engaging fully and leads to intermittent operation. - Engage the PTO at proper engine speed

Engaging the clutch at low RPM increases shock load and shortens clutch lifespan. - Keep wiring and connectors clean

Corroded or loose connections interrupt power flow and cause erratic PTO engagement.

Toro PTO Clutch Problems – (FAQs)

Are you curious about knowing something more about the PTO clutch? If yes, check the following FAQ section. .

Why won’t my Toro PTO clutch engage?

The most common causes are low voltage, a faulty PTO switch, or wiring issues.

Can a Toro PTO clutch be repaired?

Most PTO clutches are sealed and replaced as a unit rather than repaired.

Is PTO clutch overheating normal?

No. Overheating indicates excessive load, electrical issues, or internal wear.

How long does a Toro PTO clutch last?

With proper use, many last 500–1,000 hours, depending on operating conditions.