Roosa Master injection pump troubleshooting [4 problems explained]

Roosa Master injection pump is a major part of diesel powered engines. It is responsible for delivering fuel to the engine. However, there are some specific problems that can be caused by a bad injection pump and affect your vehicle’s performance.

In this case, troubleshooting the Roosa Master injection pump is crucial to fix any issues with the vehicle. While troubleshooting an injection pump, there are certain methods to follow including:

- Inspecting the pump and it’s internal parts

- Checking the fuel filter

- Inspecting fuel’s quality

- Testing fuel pressure

However, troubleshooting and fixing a faulty Roosa Master injection pump requires some knowledge and skills with diesel fuel injection systems. Let’s discuss Roosa Master injection pump troubleshooting briefly.

Overview of Roosa Master injection pump

The Roosa Master injection pump is a mechanical fuel injection pump that is specifically used in diesel powered vehicles. It was developed in the mid-20th century by an American company called Roosa Master Fuel Injection Equipment Co.

This is usually a special kind of pump that can deliver the accurate amounts of fuel to the cylinders of the engine at the proper timing and pressure.

It is also well-known for its efficiency and reliability. Therefore, Roosa Master has been widely used in different applications such as agriculture, industrial, and automotive engines.

How does a Roosa master injection pump work?

A Roosa Master injection pump works the theory of mechanical fuel injection. According to this theory, it uses a plunger and barrel assembly to produce high pressure fuel, which is then delivered to the combustion of the engine.

While working, first, a Roosa Master draws fuel from the tank via the fuel filter and fuel line. There’s a transfer pump that pressurizes the fuel and delivers it to the injection pump.

The barrel assembly and the plunger are the main parts of a Roosa Master injection pump. At the bottom of the barrel, a fuel delivery valve controls the flow of the fuel.

After that, the injection pump distributes fuel to the cylinders at the accurate moment in the combination cycle. This timing is set according to the relationship between the camshaft and the pump’s internal components.

Overall, a Roosa Master injection pump ensures the proper fuel delivery to each cylinder, providing efficient combustion and optimal engine performance.

Signs of a bad Roosa Master Injection Pump

A faulty Roosa Master injection pump will come with some common symptoms that may include:

- Loss of power and hard starting

- Poor acceleration

- Excessive smoke from the exhaust

- Rough running

- Engine misfires or stalling

- Fuel leaks

- Increased fuel consumption

Whenever you notice any of these signs, it means your injection pump may have some issues and requires troubleshooting ASAP.

5 common Roosa Master injection pump troubleshooting guide

As we already know, a faulty Roosa Master has some common problems and causes your vehicle to be misleading. So, here we’ve listed four of the most common bad injection pump problems along with their potential fixes.

#1: Hard Starting or Poor Performance

This might be the most common problem caused by a faulty Roosa Master injection pump. When the injection pump is bad, it fails to pump fuel properly into the engine.

As a result, the engine cannot run smoothly and cause such problems like hard starting, stalling or misfiring.

However, there are a few reasons that can cause this issue. These reasons will include:

- Worn out or damaged internal components

- Corrosion or debris build up between the parts of the injection pump

- Stuck internal components

Because of these issues, the engine won’t get enough fuel and the vehicle experiences problems like hard started and poor performance.

Potential Fix:

If the problem is hard starting or other engine issues and the main culprit is the injection pump, then here are some tips to fix it:

- Step 1- Do a Visual Inspection

Start by checking any visible symptoms of damage, cracks, corrosion, or obstacles on the fuel lines, fuel filter, or the fuel pump itself.

- Step 2- Check the Fuel Supply

Make sure that the fuel tank has an accurate amount of clean fuel. Then, check the fuel lines and the fuel filter for any blockage and to see if they can supply the fuel properly. Otherwise, repair or replace them as necessary.

- Step 3- Bleed the System

Bleeding the system will remove any air bubbles or contaminates that can lead the injection pump to be stuck. Better to check the user’s manual to know how to bleed the system.

- Step 4- Lubrication

Therefore, check the lubrication requirements for your Roosa Master injection pump and make sure that they are properly lubricated.

- Step 5- Check for Mechanical Damage

If the above steps fail to fix the problem, there can be mechanical damage to the pump or its internal components.

In this case, the solution would be disassembling and inspecting the pump and repairing it as needed.

However, if you need to bleed the system or find any mechanical damage that needs to be repaired, consult a professional mechanic. It will cost between $100-$145.

#2: Fuel Leakage

This is another common problem that comes with a bad Roosa Master injection pump. When you notice fuel leaking from the engine, it is usually coming from the injection pump.

There could be several reasons to this problem that will include:

- Faulty fuel line

- Damaged or corroded seals gaskets, or o-rings

- Broken injection pump

Potential Fix:

In this case, sealing the leakage won’t be a good solution. Replacing the damaged components will fix the issue. Here’s how to do it:

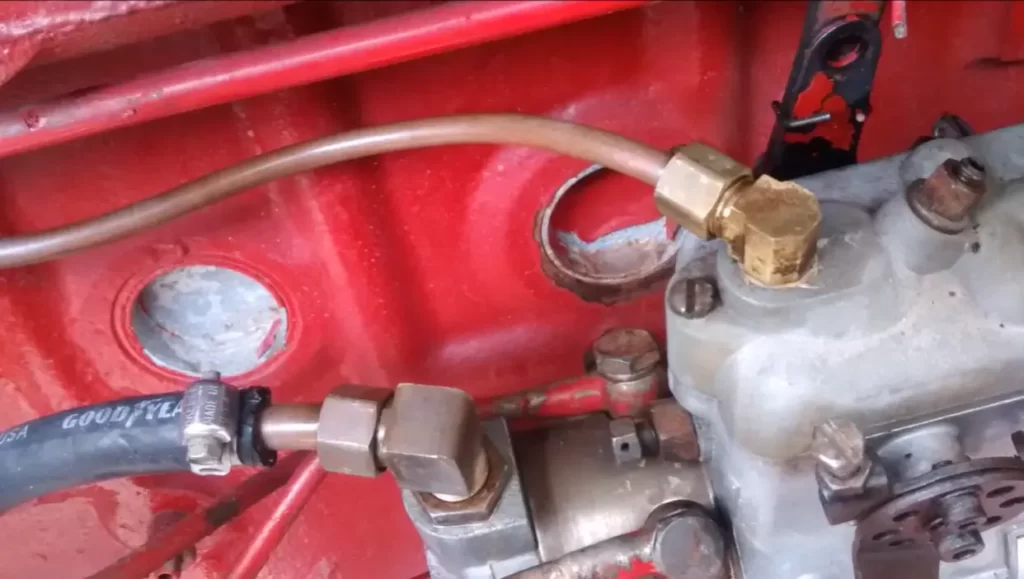

- Step 1- Find out the Leakage

Visually inspect the injection pump to locate the exact location of the leakage.

- Step 2- Replace Worn or Damaged Seals, Gaskets or O-rings

Next, check the seals and gaskets to see if they are worn out or damaged. If they are, then replace them as needed.

- Step 3- Inspect the Fuel Lines and Connections

Examine the fuel lines and connections for any loose, broken, or blockaged components. Tighten any broken connections as well as replace the defective fuel lines to prevent further leaks.

- Step 4- Check the Pump’s Housing

Now inspect the pump’s housing for any cracks or damage. If any damage is found, you may need to replace it.

- Step 5- Make It Clean

Before reassembling the Roosa Master, clean the pump and its surrounding area to ensure no dirt and debris enters the pump while assembling.

Here, the cost of fixing the fuel leaking problem on a Roosa Master injection pump is between $350 and $900. Labor cost is expected to be between $200-$300, while the parts will cost around $160 to $600.

#3: Excessive Smoke

This problem occurs when the Roosa Master injection pump is dirty or the pump itself is dirty. Additionally, inadequate fuel delivery or improper timing can cause excessive smoke from the smoke.

Potential Fix:

Smoky exhaust caused by a faulty Roosa Master can be fixed by the following steps:

- Step 1- Diagnose the Problem

First, try to determine the color of the smoke. If it is Black, then it will indicate excessive fuel, while white or blue smoke means burning oil. This is useful to narrow down the potential causes before confirming it is the result of a bad Roosa Master injection pump.

- Step 2- Examine the Fuel Injection Pump

Visually inspect the pump’s body for any cracks, leaks or worn out components. Ensure that your Roosa Master is securely mounted and the connections are tight. Also, check the timing and fuel delivery system.

- Step 3- Measure the Fuel Pressure

Now, measure the fuel pressure using a pressure gauge. If the pressure is too high or too low, it may indicate a faulty pump that needs repair or replacement.

- Step 4- Inspect the Fuel Injectors

Also, check the fuel injectors to see if there’s any leakage, or insufficient fuel spraying. Clean, repair or replace if any faulty injectors are found.

- Step 5- Clean or Replace the Fuel Filters

At the end, remove and clean the filters, or if they are excessively clogged, consider them replacing.

#4: Lack of Power

If you experience a significant decrease in power output, it could be caused by a worn-out or damaged Roosa Master fuel pump on your vehicle. Also the fuel injectors can be dirty to deliver fuel into combustion.

Potential Fix:

In this case, the potential fixes to this problem would be the following:

- Step 1- Inspect and clean the injectors:

Over time, injectors can become clogged or dirty, affecting fuel delivery.

Remove and inspect the injectors for any signs of blockages or damage. Clean them using an appropriate cleaning solution as recommended by the manufacturer.

- Step 2- Check the timing:

Incorrect fuel injection timing can cause a loss of power. Consult the vehicle’s manual or a professional mechanic to verify if the timing is correct and adjust it if needed.

- Step 3- Inspect and clean the air filter:

Verify that the air filter is clean and free from debris. Clean or replace it as necessary.

To diagnose and fix loss of power problems on your diesel powered vehicle, you should expect to pay anywhere between $400-$600. Here, your mechanic can charge from $100 to $160 per hour.

Expert Maintenance Tips For Roosa Master Injection Pump

Consistent fuel system care dramatically extends pump life:

- Use clean, water-free diesel fuel

- Replace fuel filters on schedule

- Drain water separators regularly

- Run the engine periodically if stored

- Avoid prolonged use of ether

A neglected fuel system will kill a good pump faster than age ever will.

FAQs — Roosa Master Injection Pump

How long does a Roosa Master injection pump last?

With clean fuel and proper maintenance, many last 5,000–10,000 hours before requiring a rebuild.

Can a Roosa Master pump be rebuilt?

Yes. These pumps are fully rebuildable, and rebuild kits are widely available.

What causes a Roosa Master pump to fail suddenly?

Most sudden failures are caused by seal collapse, air intrusion, or transfer pump failure, not internal breakage.

Should I rebuild or replace the pump?

Rebuilding is usually more cost-effective and preserves original fitment, especially on older equipment.

Final Verdict

The Roosa Master injection pump is mechanically tough and forgiving, but it depends entirely on clean fuel and stable internal pressure. When problems appear, they are usually fuel-related or seal-related, not catastrophic internal failures.

Bottom line:

If you diagnose methodically and address fuel delivery first, most Roosa Master pump problems can be fixed without replacement. When maintained properly, these pumps remain one of the most reliable diesel fuel systems ever built.