3 Most Common Electric PTO Clutch Troubleshooting (Visual Guide!)

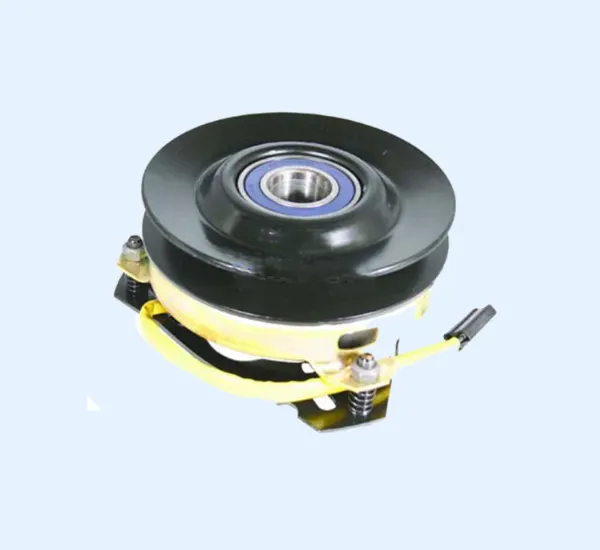

The PTO clutch is like the heart of your lawn mower as it transfers power from the motor to the blades, making grass-cutting possible. Without a good PTO Clutch, your riding mower becomes nothing more than a slow, single-passenger vehicle.

However, whenever you see some sign, you should be worried about the PTO clutch. Some of them are:

- Clutch does not engage.

- It slips when you try to mow lawn grass.

- The Clutch vibrates and makes unnecessary noise.

In this post, I’ve included a step-by-step guide for Electric PTO Clutch Troubleshooting, along with the overview.

Key Takeaways

In that case, you have to apply different solutions for each symptom. Like for not engaging problems, you have to check the wiring, change the in-line fuses and ensure proper voltage.

What’s A PTO Clutch? How Does It Work?

A PTO clutch, also known as a Power Take-Off clutch, enables the power transfer from the mower’s engine to the cutting blades. When you activate the solenoid, it produces a magnetic field that pulls the lower plate (which has a flat metal disc) and connects it with the PTO.

Imagine the PTO Clutch as the powerhouse that connects your engine to the cutting blades. When you hit that PTO switch, the mower sends an electric current to an electromagnetic coil, creating a magnetic field.

This field brings two clutch plates together and connects the engine’s power to the blade shaft. And voilà! The blades start spinning, so you can cut grass like a champ.

Now, when you’re done mowing or need a break, just turn off the PTO switch. That disconnects the electric flow, and the magnetic field disappears. The turn-off switch also makes the clutch plates separate, and the blades stop spinning.

Having a PTO clutch is like having a control switch– you can control the blades without stopping the whole mower. However, sometimes it won’t work as it should. Read the following section to know the symptoms of a defective PTO clutch.

How an Electric PTO Clutch Works (Quick Overview)

An electric PTO clutch consists of:

- An electromagnetic coil

- A rotor and armature

- Friction surfaces

- Wiring and connectors

- Safety interlock circuits

When power is supplied, the coil creates a magnetic field that pulls the clutch together, engaging the blades. Any interruption in power, grounding, or mechanical clearance can prevent proper operation.

3 most common Electric PTO Clutch problems with expert Troubleshooting guide

The PTO clutch of your mowing machine can get bad for several reasons, and you have to apply different solutions for each symptom.

In this section, I’ll give you a separate solution for each PTO Clutch issue so that you can effectively fix it.

1. Clutch Not Engaging

A bad PTO clutch often shows disengagement issues in your mower. When your Electrical PTO clutch doesn’t disengage even after you turn the switch off, you have a faulty switch.

This issue also can happen to incorrect wiring, low voltage, a bad battery or charging circuit, a damaged wiring harness, a bad in-line fuse, or improper grounding.

how to fix?

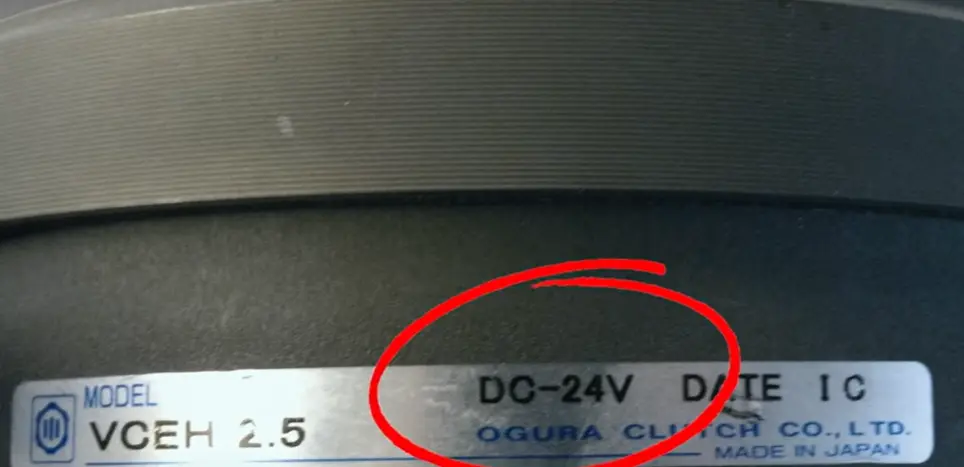

a) Double-Check Wiring: The first thing you have to ensure, the wiring is connected correctly. Also, check if the clutch is getting 12-24 Volts DC at the clutch wire. If you don’t see any power to the clutch wire, do the followings:

- Make sure the battery has 12–24 Volts at the terminals. If not, the battery might be bad, or the charging circuit isn’t working.

- Inspect the wiring harness from the battery to the clutch. Repair any damage like tears, frays, or breaks.

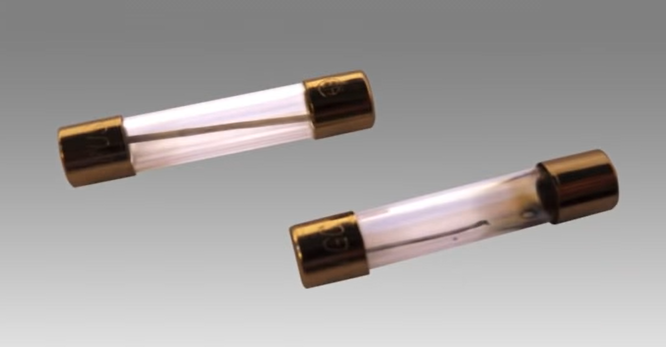

- Check the PTO switch, key switch, and any in-line fuses.

B) Verify Ground Connection: Next, you have to verify the connection between the clutch and your lawn mower. Usually, there are one or two wire connections in the clutch. Check them both to see if they are okay.

c) Replace the clutch: If the clutch receives 12-14 Volts DC at the clutch wire, has a proper ground, and the wiring is undamaged, you most likely face unidentified clutch damage. In that case, you have to Replace the clutch with a new one, like the OX clutch.

2. Clutch Slipping

Another symptom of a bad Electric PTO Clutch is continuous slipping. When dirt or gunk builds up on the surfaces between the clutch armature, rotor, or brakes, it reduces the clutch’s grip and causes slipping when you try to cut the grass.

Also, if too much grass builds up on the mowing deck or the pulleys and bearings of your PTO are worn out, the electric clutch may slip.

how to fix?

- You should first check the electrical connections, just as we did for the ‘Clutch not Engaging‘ troubleshooting.

- Then inspect the clutch armature, rotor, and brake surfaces for any dirt or gunk. And clean them thoroughly, and put the clutch back together.

- Next, remove the belt from the clutch and check the drive system (that’s where the belt goes). And look for any grass buildup on the mowing deck. If you find any, clean them up.

- Check the pulleys and bearings of the driven system; they should move smoothly without the belt. But if anything seems worn out, replace it.

After applying these fixes, the electric PTO clutch of your mowing machine won’t slip anymore, and you can clean the grass of your lawn/ yard more effectively.

3. Clutch Vibrating / Making Noise

Usually, the electric PTO makes noise or creates unnecessary vibration when the anti-rotation device becomes worn out; there’s an irregular torque on the clutch bolt.

Also, if your PTO clutch has a bent or warped clutch washer or D-spacer, a wobbling clutch, or any damage to the crankshaft, it will make an unnecessary sound.

how to fix?

- You first need to check the Anti-Rotation mechanism or the clutch armature. There should be some noise and vibration, but if you hear excessive noise, you need to increase the air gap. If that doesn’t solve your problem, replace the anti-Rotation device.

- Ensure the clutch bolt is tightened correctly and the clutch doesn’t move on the crankshaft.

- Check the clutch washer of your electric PTO. If there’s any bent or warped material, you need to replace it.

- Make sure the clutch rotates smoothly without wobbling. But if something blocks the clutch rotation, first inspect the clutch bearings, then check the crankshaft. If they’re damaged, replace them with new ones.

After applying these fixes, I’m sure you won’t face any issues with the electric PTO. However, if the issue still remains, you need to replace it ASAP.

Read also: A detailed guide on Should PTO Clutch Spin Freely or not.

Step-by-Step Electric PTO Clutch Diagnosis

Follow this order to avoid unnecessary replacement:

- Check PTO fuse and battery voltage

- Test PTO switch for continuity

- Inspect safety switches and wiring

- Measure voltage at PTO clutch connector

- Inspect clutch air gap and mounting

- Test clutch coil resistance

Only replace the clutch after electrical tests pass.

How to Test an Electric PTO Clutch Coil

Basic resistance test:

- Disconnect clutch wiring

- Measure resistance across coil terminals

- Compare to manufacturer specifications

Results interpretation:

- Infinite resistance → open coil (bad clutch)

- Very low resistance → shorted coil

- Normal resistance → electrical system likely at fault

Common Mistakes During PTO Troubleshooting

- Replacing the clutch without testing voltage

- Ignoring safety switches

- Overlooking belt routing and tension

- Not checking air gap adjustment

- Running the clutch while slipping

These mistakes often lead to unnecessary clutch replacement.

When an Electric PTO Clutch Is Truly Bad

A PTO clutch is likely bad if:

- Correct voltage reaches the clutch

- Coil resistance is out of spec

- Air gap is correct

- Blades still won’t engage or slip badly

- Overheating occurs repeatedly

At this point, replacement is usually the only solution.

Preventive Maintenance Tips

- Keep clutch area clean and debris-free

- Maintain proper belt tension

- Avoid engaging PTO at high engine speed

- Inspect wiring annually

- Check air gap if adjustable

Most PTO clutch failures are caused by heat and neglect, not sudden defects.

FAQs – Electric PTO Clutch Troubleshootin

Why won’t my PTO clutch engage?

Most commonly due to electrical or safety switch issues, not the clutch itself.

Can a weak battery affect the PTO clutch?

Yes. Low voltage can prevent full clutch engagement and cause slipping.

Does a PTO clutch need adjustment?

Some models allow air gap adjustment. Excessive gap can prevent engagement.

Is PTO clutch replacement expensive?

It can be. That’s why proper diagnosis is critical before replacing it.

Final Thoughts

Electric PTO clutch problems are often misdiagnosed. Electrical faults, safety interlocks, or improper adjustment cause many issues that look like clutch failure. Systematic testing saves time, money, and frustration.