Why Is My Kohler Engine Runs Then Dies? [Easiest Fix Ever!]

When a Kohler engine starts, runs briefly, then shuts off, it’s almost always a sign of a fuel delivery problem, airflow restriction, or a safety system interruption. The engine is able to ignite, but something prevents it from continuing to run.

This guide explains the most common reasons this happens and how to diagnose each one correctly.

What “Runs Then Dies” Usually Means

If the engine:

- Starts easily

- Runs for a few seconds or minutes

- Then shuts down consistently

…it means spark is present, but fuel, air, or engine protection systems are failing after startup.

That distinction matters, it narrows troubleshooting fast.

Most Common Reasons a Kohler Engine Runs Then Dies

1. Fuel Cap Vent Is Blocked

A clogged fuel cap vent creates a vacuum in the fuel tank, slowly starving the carburetor of fuel.

Symptoms:

- Engine runs fine at first, then dies

- Restarts after sitting for a few minutes

Quick test:

Loosen the fuel cap slightly and try running the engine again. If it stays running, replace or clean the cap.

2. Damaged piston rings

These rings work as a seal between the piston and the cylinder wall. Due to consistent usage, particles, and improper installation, they can be damaged. As a result, the piston rings cannot create the seal and cause oil leakage in the combustion chamber. Finally, the engine stops without any warning.

How to fix:

- Replacement is the only option for damaged piston rings. First, remove the piston from the engine’s block and detach those rings from the piston.

- Install new rings on the piston and reassemble it in the engine block. Restart the engine and see if it works.

Caution:

Wear safety gloves to avoid cuts from the piston rings.

3. Dirty or Clogged Carburetor

Old fuel leaves varnish deposits that restrict fuel flow, especially through the main jet.

Common signs:

- Engine dies under load

- Requires choke to keep running

- Stalls repeatedly after warm-up

A carburetor cleaning or rebuild often solves this completely.

4. Insufficient or stale oil

Oil is crucial for lubricating the engine’s moving parts. It is also essential to prevent wearing out the internal components. If the engine lacks sufficient oil, excessive friction can happen, which restricts the engine’s movement.

Inadequate oil is also the reason for the engine’s overheating and sudden inactivity. Moreover, stale oil often makes the engine difficult to start.

How to fix:

- If the engine dies for these reasons, adding new oil is the solution. Choose a compatible oil for the Kohler engine first.

- Drain old oil and add sufficient and fresh oil to well-lubricate the engine. After that, restart the engine and notice it the problem is solved.

Caution:

Do not smoke while changing the oil. Also, keep all types of flame away. Choose a well-compatible and high-quality oil to maximize the engine’s performance.

5. Overheating

Due to overheating, Kohler engines can suddenly die. Excessive heat sometimes vapor locks the carburetor and stalls the engine. When the engine is overheated, its metal parts expand and cause friction, which results in an engine failure.

How to fix:

- First, address the reason for overheating. For example, if the engine becomes too hot after a specific time, pause mowing before reaching that time. There are many other reasons for overheating, which you must find out and fix accordingly.

- Check the engine’s coolant level. Add more coolant with an accurate mix ratio if the level seems low.

- A defective thermostat may not distribute coolant through the engine. In such a case, replace the faulty one to protect the engine.

Caution:

Before working on the engine, wait until it becomes cool. Avoid the coolant from skin contact at any cost, as it is highly toxic.

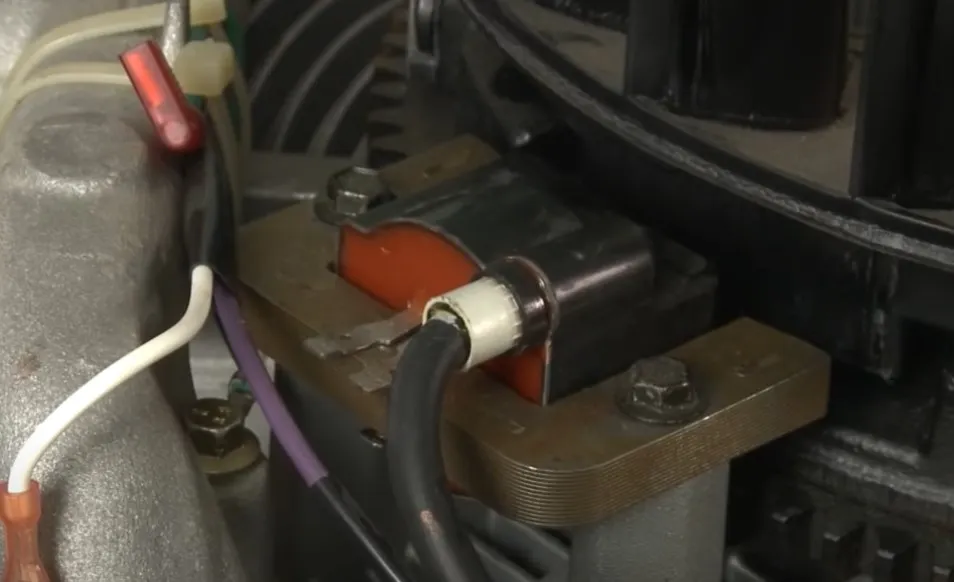

6. Ignition coil malfunctions

The ignition coil’s key function is to create a high-voltage spark needed to operate the spark plug. If it does not work correctly, the generated spark can be weak and result in the engine shutting down during operation.

How to fix:

- Overheating is often responsible for the ignition coil failure. Check the engine’s cooling system and fix it if you have found any issues.

- Corrosion can also cause an ignition coil to malfunction. In that case, clean the coil with an electric contact cleaner.

- Excessive engine vibration hampers the connection between the ignition coil and spark plug. Ensure that the coil is mounted correctly and tightened.

- If the ignition coil looks too old and worn out, replace it with a new one.

Caution

Use the right tools to detach the ignition coil to avoid physical damage.

Step-by-Step Troubleshooting Order (Do This First)

- Loosen the fuel cap and test run

- Check fuel flow from tank to carburetor

- Inspect and clean carburetor

- Verify choke operation

- Check air filter condition

- Confirm oil level and sensor wiring

Following this order prevents unnecessary part replacement.

Preventive Maintenance Tips

- Use fresh fuel and stabilizer

- Drain carburetor before long storage

- Replace fuel lines every few seasons

- Keep cooling fins clean to prevent overheating

- Change oil at recommended intervals

Engines that “run then die” are often victims of neglected fuel systems.

FAQs – Kohler Engine Starts Then Shuts Off

Why does my Kohler engine run for a few seconds then die?

Most often due to restricted fuel flow or a blocked fuel cap vent.

Will bad gas cause this problem?

Yes. Old or ethanol-degraded fuel is one of the leading causes of carburetor blockage.

Can low oil shut the engine off even if it’s running fine?

Yes. The low-oil shutdown system can stop the engine instantly if oil level drops or the sensor malfunctions.

Should I replace the carburetor or clean it?

Always clean first. Replacement is only needed if internal passages are damaged or corroded.

Final Thoughts

When a Kohler engine runs and then dies, the issue is rarely catastrophic. Fuel delivery, airflow, and safety systems account for most failures, and they’re usually repairable with basic tools and methodical testing.

Continue Reading…

Kohler 7000 Series Starting Problems [Try This Easy Fixes!]

8 Most Common Kohler Courage 26 Hp Engine Problems [+ Visual Guide]