8 Common Kohler EFI Engine Problems [Troubleshooting Guide]

Kohler EFI (Electronic Fuel Injection) engines are designed to deliver better fuel efficiency, smoother performance, and easier starting compared to carbureted engines. They’re commonly used on zero-turn mowers and commercial lawn equipment.

However, when EFI systems develop problems, they tend to feel more confusing than traditional carburetor issues. The key is understanding that most EFI failures are sensor-, fuel-, or electrical-related, not mechanical engine damage.

Common Kohler EFI Engine Problems

- Change the low-power battery and bad fuel.

- Clean the MAF and TPS sensors.

- Remove dirt from the fuel filter, fuel line and air filter.

- Replace defective fuel pressure regulator and MAF sensor.

- Change the damaged starter switch.

- Add sufficient fuel and clean the oil filter.

- Replace faulty ignition components.

- Clean the smart choke unit.

Check the below sections for the in-depth discussion and fixes about Kohler EFI Engine Problems and there fixes.

1. Hard starting

A weak battery, clogged fuel line, bad fuel and dirty air filter can make the Kohler EFI engine challenging to start. Besides, faulty ignition components are sometimes liable.

In this case, you will face difficulty in starting the engine. The continuous starting attempts can reduce the engine’s lifespan. Also, an engine with the issue consumes more fuel.

Read: 7 Common 27 HP Kohler Engine Problems Troubleshooting

How To Fix?

- Change the low-power battery: If the battery has low voltage, replace it with a fully charged one. Besides, change cables if they become corroded.

- Replace the fuel filter and use fresh fuel: If the fuel filter is clogged, replace it immediately. Clean the fuel line as well. Finally, use fresh and high-quality fuel free from debris.

- Clean dirty air filter: Remove dust and debris from the air filter. If cleaning it seems impossible, replace the filter.

- Replace faulty ignition components: Check and confirm that the ignition components, such as spark plug and ignition coil, are working properly. If they do not, replace the faulty one.

2. Rough idling

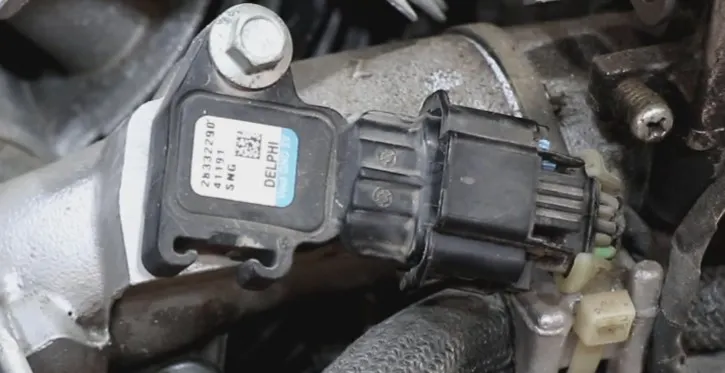

The Kohler EFI engine can have rough idling issues due to faulty sensors like MAF and TPS, vacuum leaks, and a dirty fuel injector.

If it occurs, you can experience excessive shaking while the mower is in idle condition. It can also stall the engine.

How To Fix?

- Check and clean the sensors: Inspect the MAF (mass airflow sensor) and TPS (throttle position sensor) carefully. If they are dirty, use the particular sensor cleaner to clean them. Or, you can go to a technician for professional cleaning. If they seem defective, replace them instantly.

- Change damaged vacuum hoses: If the vacuum hose of the engine is cracked, replacement is the only way to go.

- Clean fuel injector: Use a fuel injector cleaner to clean the dirty one so it can perform smoothly.

- Check the IACV: If the engine’s idle air control valve (IACV) is jammed, clean it using the throttle body cleaner. Replace the component if it is damaged.

3. Stalling

Limited fuel supply, ignition system issues and air filter blockage are the primary reasons for Kohler EFI engine stalling. Besides, the defective crankshaft position sensor can also cause the problem.

Engine stalling is an inconvenience for users as it hampers productivity. It also enhances the risk of engine damage.

Read: 25 HP Kohler Command Pro Engine Problems

How To Fix?

- Ensure proper fuel supply: Replace the fuel filter if it is too dirty. Clean the fuel line if it is clogged. Besides, always use fresh fuel to prevent further blockage.

- Check the ignition system: If a component in the ignition system, like the spark plug, spark plug wire, or ignition coil, is faulty, change the defective one.

- Clean the air filter: Use a brush or compressed air to clean the blocked air filter.

- Inspect the crankshaft position sensor: If the sensor seems defective, go to a qualified technician for professional help.

4. Over fueling

Kohler EFI engine can have an over-fueling issue if the fuel pressure regulator becomes faulty or the fuel injector gets clogged. It also happens due to a malfunctioning MAF sensor.

The over-fueling problem burns more fuel than necessary and increases your fuel cost. It also produces more emissions and can enhance the risk of fire hazards.

How To Fix?

- Replace the fuel pressure regulator: If you notice that the fuel pressure regulator delivers too much fuel, replace it immediately.

- Clean the fuel injector: Use a commercial fuel injector cleaner to clean it, as the dirty one can spray excessive fuel. If it is damaged, replace it with a new one.

- Change MAF sensor: A faulty MAF sensor sends the wrong signal and forces the engine system to inject more fuel. If you find it defective, replace it.

5. Starter switch problem

The engine’s starter switch will not work if it is damaged or its connection is loose. Besides, corrosion at the switch terminal and bad wiring can also cause the problem.

When the starter switch has a problem, the engine may not start. Or, you can have difficulty to start the engine.

How To Fix?

- Replace the faulty starter switch: Changing the switch is the only option when it is completely damaged.

- Remove corrosion from the terminal and solenoid: If the starter switch terminals are corroded, remove them using a brush and spray cleaner. Apply the same technique if the starter solenoid is also corroded.

- Reconnect loose connections: If you notice a loose connection in the switch section, reconnect it immediately. If any wire is damaged, replace it with a new one.

6. Fuel starvation

A jammed fuel filter, empty fuel tank, damaged fuel line and defective fuel pressure regulator are the common reasons for the Kohler EFI engine’s fuel starvation.

In such a case, the engine can run rough and stalling can happen. It is harmful to the engine in the long run.

How To Fix?

- Check fuel level: First, notice whether the tank has sufficient fuel. If not, add more fresh fuel to the tank and restart the engine.

- Ensure proper fuel supply: Check if the fuel filter is clogged. Clean the jammed fuel filter if possible. Otherwise, replace it completely.

- Fix or replace the fuel line: If the problem occurs due to a damaged fuel line, try to fix it if possible. Or you can replace it.

- Change faulty regulator: Sometimes, the defective fuel pressure regulator causes the problem. In such a case, change it.

7. Ignition problem

The Kohler EFI engine can have several ignition problems in its lifespan. Its spark plug, ignition coil, distributor cap and ECU can be faulty at any time.

A Kohler EFI engine with an ignition problem will provide you with poor mowing performance. It can also stall and misfire.

Read:

How To Fix?

- Change the faulty spark plug and ignition coil: Replace the spark plug if it is damaged or too old. Similarly, change the ignition coil when it is defective.

- Replace cracked distributor cap: If the cap is damaged, change it soon.

- Reset the ECU: If the engine’s electric control unit (ECU) seems problematic, contact a qualified technician to reset its program.

8. Smart choke problem

The Smart Choke is a special feature in Kohler EFI engines. But it can malfunction due to a faulty sensor or defective choke actuator, bad wiring and dirt.

When the function has a problem, it fails to choke. As a result, starting the engine can be difficult.

How To Fix?

- Clean the smart choke unit: If dirty, the unit may not function properly. Clean the unit very carefully without damaging the sensor.

- Check the smart choke acurator: Notice attentively if you find any damage on the acurator. Replace it when you find any wear and tear.

- Inspect the wiring harness: Smart Choke can also malfunction due to bad wiring or defective wiring harness. If you identify a specific problem in the wiring harness, repair it or replace the harness.

Maintenance Tips for Kohler EFI Engines

To reduce EFI-related problems:

- Keep the battery fully charged

- Replace fuel filters on schedule

- Use high-quality fuel

- Store equipment with stabilized fuel

- Inspect wiring and connectors periodically

EFI systems are reliable, but neglect shows faster than with carburetors.

FAQs – Kohler EFI Engine Problems

Why won’t my Kohler EFI engine start?

Most no-start issues are caused by low battery voltage, fuel pump failure, or sensor problems rather than mechanical damage.

Are EFI engines harder to fix than carbureted engines?

Diagnosis is different, but most repairs involve fuel or electrical components, not internal engine work.

Can a Kohler EFI engine run without sensors?

No. The ECU relies on sensor input to operate correctly. Failed sensors often trigger limp mode or no-start conditions.

How long do Kohler EFI engines last?

With proper maintenance, many run 2,000–4,000 hours or more, depending on usage and care.