4 Reason Why Mower Engine Dies When PTO Is Engaged

Frequently noticing that your mower engine dies when PTO is engaged is certainly alarming. Fixing this is easy once you know the exact cause.

So, why might the engine die as soon as the PTO is engaged? Here are the most common reasons:

- Bad blade engagement

- Spin failure of the pulley

- Charging issues

- A faulty safety switch

Most of the time, routing the belt with a properly adjusted blade resolves the issue. Cleaning out the fuel tank and air filter is also a good idea.

But when that doesn’t work, you may need to repair or replace the pulley, the battery, or the safety switch.

How Does the PTO in Your Mower/Tractor Work?

True to its name, a PTO or Power Take-Off in your mower or garden tractor circulates power to its cutting mechanism, usually the deck and the blades.

As you use the switch or lever to start cutting grass, you actually activate the PTO, which engages the deck and sets the blades in motion.

The system comes in super handy for emptying the grass bag or doing similar tasks as it cuts the hassle of starting or stopping the engine every time.

Inside the PTO system, there are two main components: the upper plate with an electromagnetic clutch and the lower plate with a mower deck pulley. Between them is a rotor or flywheel with holes and gaps.

As you activate the PTO switch, the battery powers up the electromagnet, attracting the lower plate to the spinning flywheel. And that’s when the deck pulley starts rotating, and the blades spin to cut the grass.

troubleshooting guide for Engine Dies When PTO Is Engaged

Under normal conditions, the mower or tractor engine runs without issue when the PTO is engaged. But the stalling issue comes with age or misplaced wear and tear.

Now, before anything else, you may want to start by troubleshooting the minor issues. For example, cleaning out the clogged fuel system, air filter, or jammed spark plug and refilling the fluid often works out for most people.

However, if these don’t do the trick for you and the engine still dies with the PTO engaged, there are other potential causes and solutions you might try:

1. Bad Blade Engagement

The blades of your mower or tractor, when poorly engaged, can cause the engine to stop when the PTO runs. This normally happens due to two reasons.

- Lodged, dulled, or misadjusted blades

- Incorrect blade length

- Incorrectly routed belt

Now how would you know if the blade engagement is faulty? These are the two primary signs you may notice.

- Blades stop spinning soon as they start

- Uneven grass after mowing

how to fix?

When you identify these blade engagement issues, inspecting the blades for lodged pieces and blockages is the first thing to do. But do keep in mind the burden of removing them in the first place.

If the problem stems from an incorrect size, the only solution is to replace the blade. Checking your owner’s manual for the right size is your best bet, but the below table should give you a general idea.

Then again, setting an incorrectly routed belt is where things get even trickier. Still, with proper tools and some general know-how, doing it yourself is still possible. Here’s how.

- Step 1: Begin by lowering the deck as low as possible. Then, from the drive pulley, take out the belt protector to check the routing.

- Step 2: Also, raise the belt over the pulley to remove the pins securing the deck at its back.

- Step 3: Similarly, you need to take out the pins holding the PTO cable and the attachment point on the front deck.

- Step 4: Now pull out the deck and get ready to route it properly. Ideally, you should check your owner’s manual to see how it should align.

2. Spin Failure of the Pulley

To keep the blades in a smooth motion, tractors and lawnmowers use pulleys, which are turned by spindles. So, when a pulley gets stuck or won’t spin freely, you’ll likely experience engine stalling as soon as the blades are engaged by the PTO.

If you’re wondering why this might happen, here are the possible reasons:

- Seized or failed bearings

- Dust or debris obstructing the pulley spin

- Wear and tear from long-term use or poor maintenance

And when the pulley fails to spin, these are the telltale signs you’ll likely notice:

- Noise from the deck area.

- Jarring or unresponsive blades despite PTO engagement

- Unusual burning smell after mowing

how to fix?

When you notice these signs of pulley failure, you have to first clear out whatever is blocking the spindle from spinning.

But if the system is old or beyond repair, replacing the pulley is your only viable solution. Yet, only replacing the bearing does work fine pretty often. Either way, you need to follow these steps.

- Step 1: Start with removing the drive belt from the pulley and look for damages. If you need to turn the blades, raise the lever.

- Step 2: Then, as you engage the lever on the deck the blade brakes should release. This allows you to turn the spindles with your hands.

- Step 3: Keep spinning the idle pulleys. If you can’t, somehow, or they keep making grumbling noise, add some WD-40. If that won’t do, they’ll need replacing.

- Step 4: Now, when replacing the pulleys, you’ll need to take the blade deck out. For this, you must grab the nut lying under that pulley using a wrench.

- Step 5: As you do this, also take out the bolt atop the pulley. Then, remove the cup washer, the nut, the belt protector, and finally the pulley one by one.

- Step 6: Now, reverse the procedure, replacing the older components with newer ones (those needed). Position the belt behind the new pulley.

If you’re wondering how much these would cost, the average price for a mower’s pulley part ranges from $10 to $40, while bearings are usually between $8 to $20.

3. Charging Issues

Just like a weak battery or improper power transfer stalls a vehicle, the same thing can happen to your mower. When the charging unit fails to provide the power required to keep the electromagnet operating, the clutch won’t engage. Several things can lead to this problem. Such as:

- Bad terminals or connections

- Faulty voltage regulator

- Dead battery

- Alternator failure

In the case of battery trouble, here are the signs you’ll likely notice:

- Sluggish start before stalling

- Failing lights

- Warning lights on (if any)

how to fix?

When fixing charging issues, inspecting the terminals and all cable connections for corrosion or breakages is your first step. You may need to clean any discolored or rusted connection with baking soda or WD-40.

And if necessary, you might also replace any loose or cracked connection. However, if that won’t fix your battery issue even after a full charge, you must ensure the battery itself is okay.

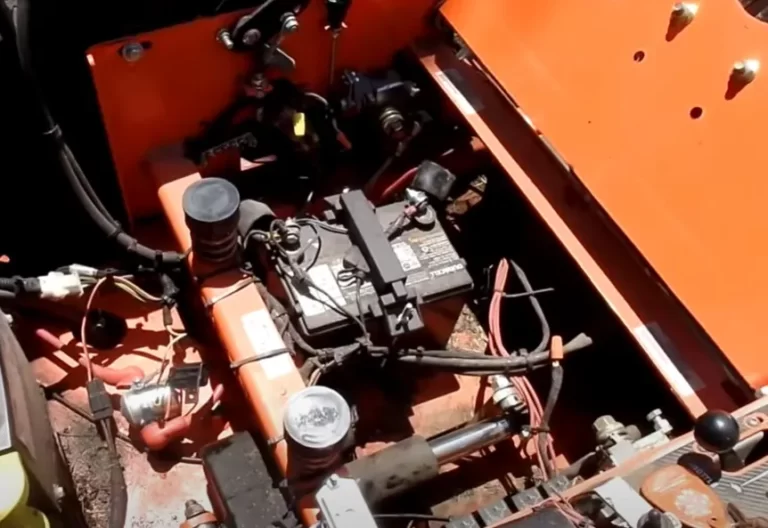

You can use a multimeter to check whether the voltage still reads around 12v with the engine on. If not, it’s time to replace it. Here’s how you can do it:

- Step 1: Before unplugging anything, turn your mower off. Then begin with removing the terminal leads; first the negative, then the positive.

- Step 2: Now, remove the holding clamp and take the old battery out of the cradle.

- Step 3: Position your replacement battery in the cradle, making sure it’s seated properly and securely.

- Step 4: Next, fasten the clamp onto the battery to secure it in place. Be careful not to overtighten, which could crack the battery casing.

- Step 5: Now, just plug the battery leads back in. Only this time, start with the positive.

A new battery typically ranges from $30 – $200, depending on the specific type and required ratings. Your best bet is to check your mower’s owner’s manual or speak to a local professional for advice.

4. A Faulty Safety Switch

Now, another frequently reported problem that can cause a mower to stall with PTO engaging is a faulty safety switch. Intended for safety purposes, these switches are typically activated by the seat, the clutch, or the transmission. Potential reasons behind a faulty safety switch include:

- Deactivated seat safety switch

- A loose wire or a broken circuit

- A malfunctioning transmission

In these cases, the symptomatic evidence will generally be:

- Mower stops with the clutch pedal release

- Mower won’t start at all

- Engine cutting off when in reverse

how to fix?

Now, of course, if you suspect a fault in your mower’s safety switch, your first action would be to check if you’ve accidentally unplugged it.

But if reactivating the switch doesn’t solve the issue, there could be a broken circuit or a loose wire involved, which needs addressing.

However, when the switch itself is faulty, the only option you’ve got is to replace the entire safety switch unit. Here’s how you can do it.

- Step 1: First, confirm if the switch is really at fault. Disconnect the kill wire from the ignition and see if it sparks. If not, the fault is there.

- Step 2: To begin the replacement job, turn the mower off and remove the spark plug.

- Step 3: Typically, you’ll find the safety switch under the seat or on the handlebar close to the control bar.

- Step 4: Now, you must detach any fasteners or screws holding the switch in place and disconnect the wiring.

- Step 5: Once disassembled, connect the wiring to your new safety switch and attach it securely to the position it’s supposed to be.

When purchasing a new safety switch, make sure to buy one that’s compatible with your mower by looking up the manual. The cost typically ranges from $10 – $25.

How to Prevent PTO-Related Engine Stalling

- Always engage PTO at full operating RPM

- Keep mower deck clean and free of debris

- Replace fuel filters annually

- Inspect PTO clutch and wiring during routine maintenance

- Use fresh, clean fuel

Regular maintenance prevents overload conditions that lead to sudden shutdowns.

FAQs

Why does my engine shut off instantly when I engage the PTO?

Instant shutdown usually points to a PTO clutch issue or safety switch problem, not fuel starvation.

Can a bad PTO clutch stall the engine?

Yes. A seized or electrically failing PTO clutch can overload the engine immediately.

Is it safe to bypass the PTO safety switch?

No. Bypassing safety switches is dangerous and can cause serious injury.

Should the mower be at full throttle before engaging PTO?

Yes. Engaging the PTO at low RPM increases stalling risk and clutch wear.

Continue Reading…